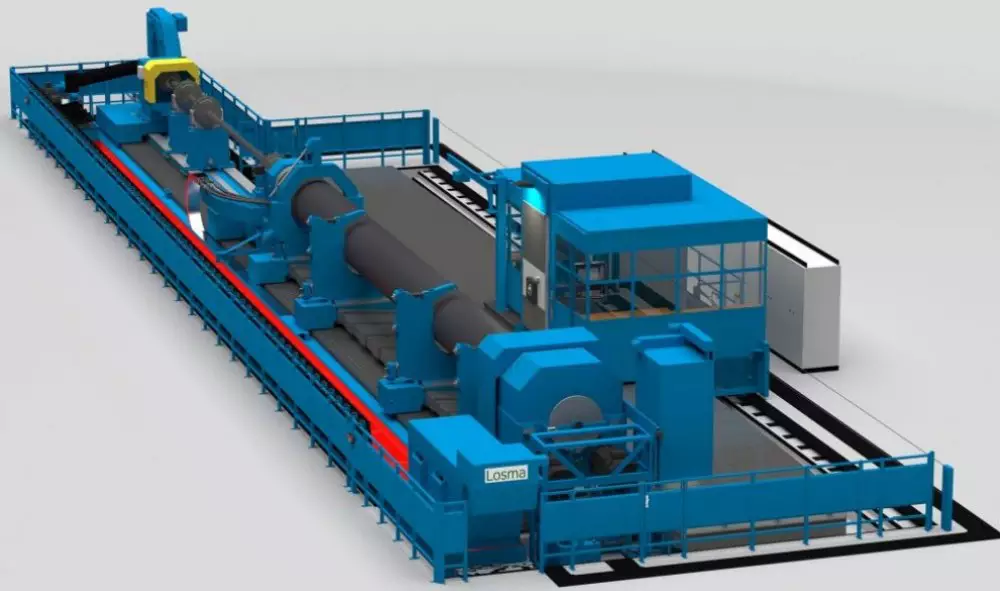

The uniqueness of the workplace is in the connection of two machines into the one - a lathe and a drilling machine.

The uniqueness of the workplace is in the connection of two machines into the one - a lathe and a drilling machine. The machine v in its basic arrangement can be performed both turning and milling, drilling and grinding operations. and high accuracy predetermine this workplace for machining long slender parts, especially from z the shipbuilding and power industry.

These operations are carried out by a longitudinally and transversely movable milling tower. The tower stand is fitted with a pair of lamellar supports s with holders of Capto C8 lathe tools. The headstock travels in the vertical direction s with the milling spindle. For flange face milling operations or angle drilling and milling operations, the IFVW122 milling head s can be automatically attached to the headstock with a +/- 100 ° spindle swivel around the vertical axis. For grinding operations the grinding head B11 s can be connected to the headstock head with manual turning of the disc v can be connected to the headstock head with manual turning of the disc in the range of +/- 30 ° around the vertical axis. Both heads are stored v n the pickup, where they are picked up in automatic mode. There is a coolant supply both external and spindle axis. For suitable support of workpieces, the workplace is completed with two types of supports of required diameter ranges - in rolling design. The workstation is equipped as standard with Renishaw probes to check workpiece and tool alignment.

By relatively simple workplace rebuilding can be also during one setup carried out BTA deep drilling operations up to 500 mm diameter and 8 m length of a drill hole. Up to 16 m can be drilled when the workpiece is rotated. Rebuilding the workstation assumes the removal of the tailstock top and its replacement by a pressure head s with a coolant supply for deep drilling operations. The used coolant and chips are discharged through the inside of the drill rod to the collection trolley and coolant collection tank located along the entire workstation.

The versatility of the workplace is underlined by a rolling device designed to strengthen or smooth defined surfaces of the workpiece. The device can handle this activity on external cylindrical and conical surfaces and is also ready for rolling radial flange transitions. The range of roller diameters from 250 to 1 200 mm and the maximum deformation force of 120 kN are unique.

The entire workplace is managed by the Sinumerik 840D SL control system. Control is possible from the machine‘s main panel on the operator platform or z from auxiliary panels at important workstations nodes. The customer can also be offered a postprocessor of the workplace v in the Siemens NX system, including possible machining simulations. A mechatronic model (digital twin) is also prepared for the whole workplace, on which the PLC program and the functionality of the whole device are tested.

| Technical parameters | |

| Max. swing diameter | 2500 mm |

| Max. turning lenght | 20000 mm |

| Max. workpiece weight | 70t |

| BTA deep drilling | |

| Max. drilling diameter | 250 mm |

| Max. deep drilling diameter | 500 mm |

| Max. drill hole length | 8000 mm |

| Drilling from both sides | 16000 mm |

| Milling headstock + head IFVW122 | |

| Max. power | 37 kW |

| Max. torque | 2200 Nm |

| Max. spindle speed | 2000 rpm |

| Clamping | ISO 50 |

| Grinding tool B11 | |

| Power | 11 kW |

| Max. plate diameter | 450 mm |

| Max. plate width | 40 mm |