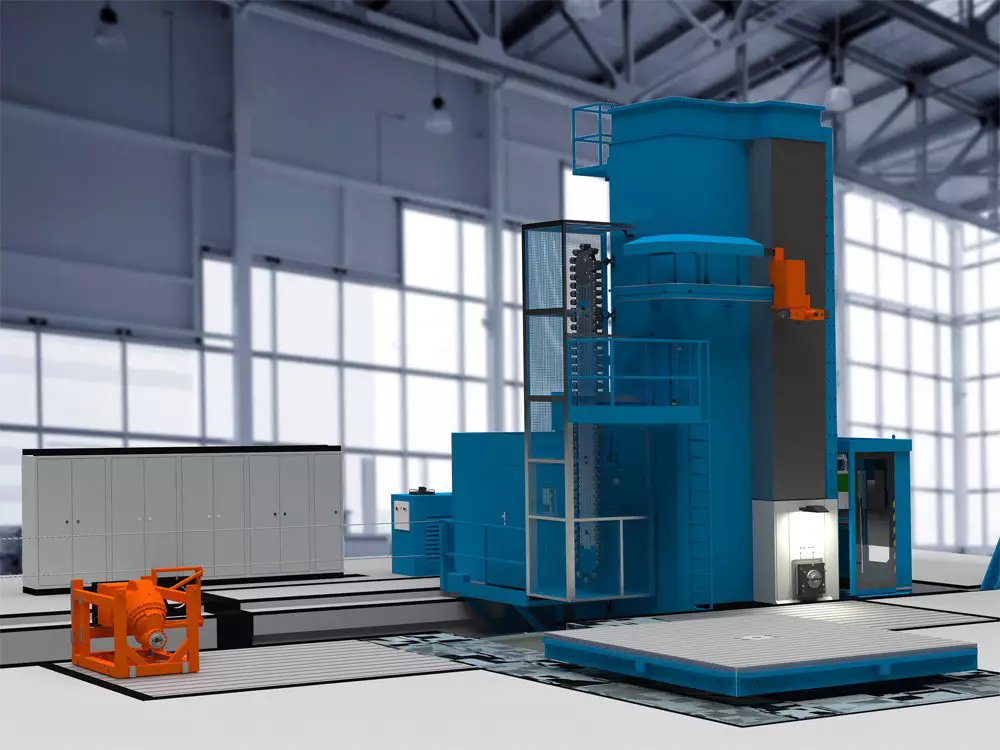

Horizontal boring and milling machines ŠMT are successful all over the world, since they are capable to machine accurately and efficiently large workpieces of complex shapes, such as turbines, parts of windmills or large motor blocks.

Two-step gearbox built into the ram allows this type of machine to reach extreme out travels in the ram (Z) and the spindle (W) travels together with very high revolutions. This up-to-date concept of the newest type of ŠMT horizontal boring and milling machine enables use of the most advanced machining tools available on the market and it also extremely improves the customer’s productivity.

High revolution fully hydrostatic machine

Following the latest trends in feed kinematics available, ŠMT machines reach high feed rates without compromises as for the traditionally superior accuracy and the machine’s lifetime. Using the most advanced systems of the ram dropping compensations, ŠMT machines are able to keep accuracy in microns even with fully extended ram from the headstock (a patent of ŠMT).

|

|

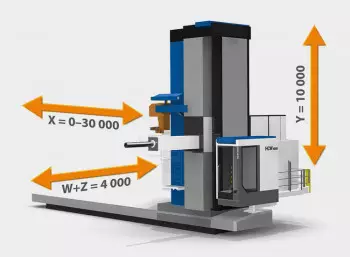

HCW 2000 |

HCW 3000 |

HCW 4000 |

|

Spindle diameter (mm) |

160/180 |

180/200/225 |

225/250/262 |

|

Main motor power (kW) |

64 |

103 |

120 |

|

Max. spindle speed (rpm) |

3 500 |

3 000 |

2 500 |

|

Sleeve extension in Z axis (mm) |

1 750 |

2 000 |

2 500 |

|

Sleeve extension in W axis (mm) |

1 250 |

1 500 |

1 600 |

|

Max. headstock traverse in Y axis (mm) |

5 000 |

7 000 |

9 000 |