Horizontal boring and milling machines ŠMT are successful all over the world, since they are capable to machine accurately and efficiently large workpieces of complex shapes, such as turbines, parts of windmills or large motor blocks.

Machines' gearbox (Two-step; Three-step) allow transmitting of extremely high torque in the spindle or tool for rough machining together with the possibility of high revolutions for final machining.

High torque fully hydrostatic machine

This gives excellent results during machining process while taking huge chips as well as during very accurate fine machining on the customer’s components, meeting the highest demands.

Heavily ribbed and large-sized castings together with in-house precise machining in micron values gives the machine superior stability features in long-term period of its use. Thanks to modern approach of ŠMT engineers and use of advanced functions and technologies, the machine brings even higher performance and reliability during its lifetime.

| HCW 1 - New | HCW 2 - New | HCW 3 | HCW 4 | |

| Spindle diameter (mm) | 160/180 | 180/200/225 | 200/225/250/262 | 262/280/300 |

| Main motor power (kW) | 71 | 100 | 129 | 147 |

| Max. spindle speed (rpm) | 3 500 | 2 500 | 2 000 | 1 600 |

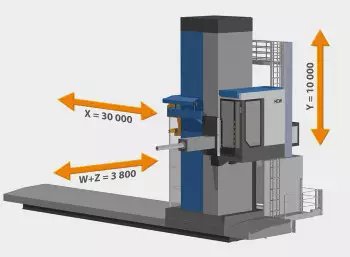

| Ram extension Z (mm) | 1 500 | 1 500 | 1 600 | 2 000 |

| Spindle extension W (mm) | 1 200 | 1 200 | 1 500 | 1 800 |

| Max. headstock traverse Y (mm) | 5 000 | 7 000 | 9 000 | 10 000 |